Product Introduction

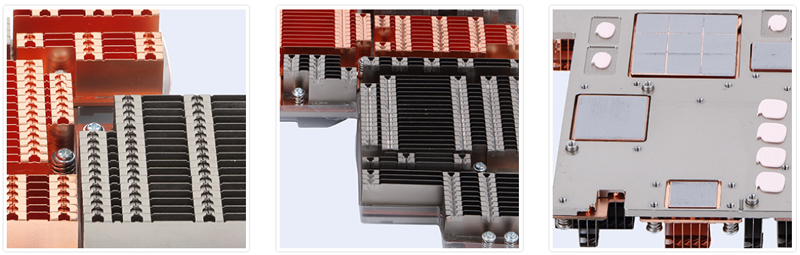

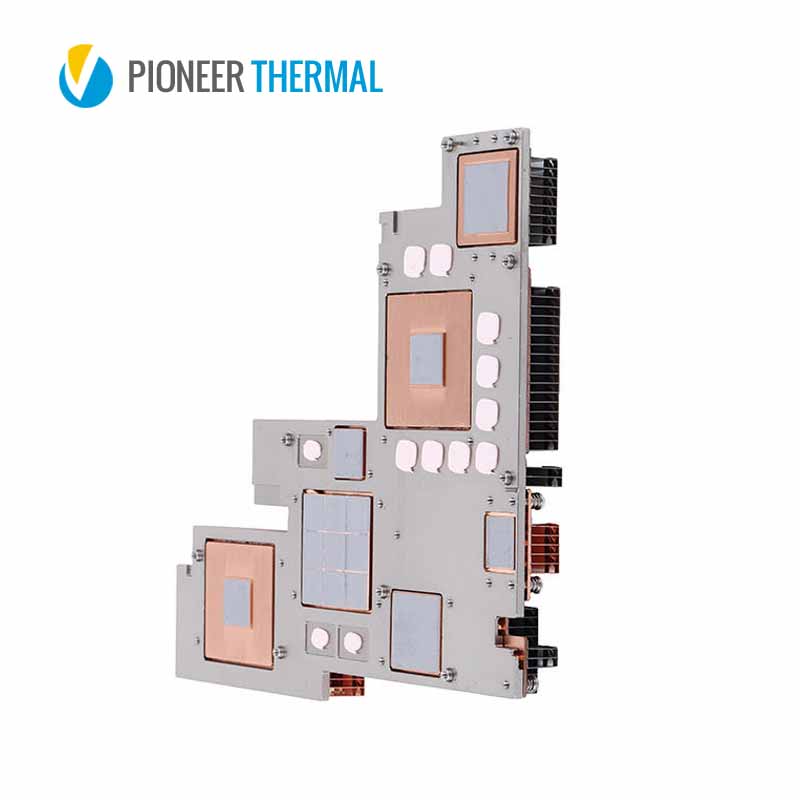

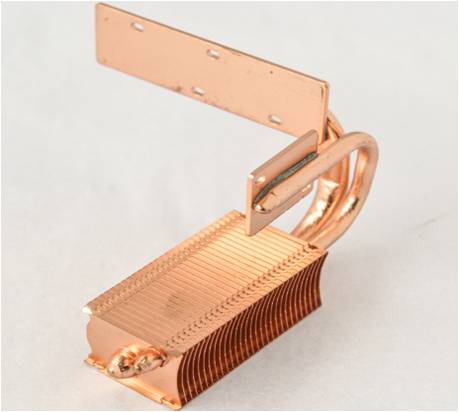

Stamped Stacked Fin Heat sink is made from sheets of aluminum and copper, where the metal is stamped into a particular configuration based on the intended application. For maximum design flexibility, fins can be stamped into a broad range of geometries and thicknesses. A stacked fin heat sink is a useful approach for medium to high volume production.

Copper and Aluminum Stacked Fin Heat Sink Process:1. CNC machining copper base plate and aluminum base plate for stacked fin heat sink

2. Stamping aluminum fin and copper fin by punch machine

3. Surface treatment: copper base plate and copper fin anti-oxidation, aluminum base plate and aluminum fin nickel plated

4. Soldering base plate and fin together by reflow oven

5. Testing

6. Degrease and anti-oxidation

7. Install screw and spring, apply thermal grease, laser marking production code/part no.

8. Inspection, pack and ship.

Copper and Aluminum Stacked Fin Heat Sink Details:

Thermal Solution Manufacturer

Pioneer Thermal Heatsink was established in 2003 in China with the goal of providing advanced thermal engineering and design services to customers. We specialize in the design and manufacturing of high quality, high performance but cost effective heatsinks manufacturer, which are widely used in the field of consumer electronics, Led, power, medical, telecommunications and automotive industries. We have a 91,000 square foot facility and certified with ISO9001 & 14001.

Our seasoned professionals can model and critique the thermal implications of your design using CFD, Solidworks, ProE, and AutoCAD. This enables us to create functional thermal solutions that meet the demanding cooling requirements in the most efficient and cost-effective way possible. We can manage your thermal needs from the conceptual design stage, through prototypes and into production.

Researching and Developing Capacity

Skilled Engineers Support: over 15+ years in Heat dissipation analyze and metal fabrication industry.

Latest CFD Thermal Analysis Tools: 3D CAD design tools such as Solidworks, ProE, and AutoCAD.

- 2003Built factory in China

- 2007ISO9001 & ISO14001 Certified

- 2017IATF16949 Certified

- 2018Set up USA office

- 2023Build a second facility in China,15,000㎡

- 2024New production location in Vietnam

Quality Assurance

Pioneer Thermal heatsink is certified with ISO9001, ISO14001 & IATF16949, RoHS & REACH compliace.

- • For incoming material, we request supplier to send the related documents and dimension report, IQC will do the second inspection inhouse.

- • For every production, we will perform FAI to ensure the heat sink dimension is within specification, IPQC to do the inspection every 2 hours.

- • Before the parts are shipped, OQC will do the final sampling inspection to guarantee the high quality heat sink.

Workshop

Trusted by world-class brands

What Our Clients Say

I worked with many heat sink manufacturers, Pioneer Thermal is one of my favorite, not only they provide high quality heat sink, but also have excellent service.

Pioneer Thermal is a long time heat sink partner for our company. I enjoy very much with working with them, they always give good suggestions to make my design more producible and cost-affordable.

Pioneer Thermal helps us a lot on our project, they always provide manufacturing advice on quotation stage, so we do not face the situation that we release order and be told we need to change something to make this design happen.

I worked with many heat sink manufacturers, Pioneer Thermal is one of my favorite, not only they provide high quality heat sink, but also have excellent service.

Pioneer Thermal is a long time heat sink partner for our company. I enjoy very much with working with them, they always give good suggestions to make my design more producible and cost-affordable.

Pioneer Thermal helps us a lot on our project, they always provide manufacturing advice on quotation stage, so we do not face the situation that we release order and be told we need to change something to make this design happen.

I worked with many heat sink manufacturers, Pioneer Thermal is one of my favorite, not only they provide high quality heat sink, but also have excellent service.

English

English Español

Español Deutsch

Deutsch Français

Français 日本語

日本語

+86-18902844286

+86-18902844286

E-mail

E-mail