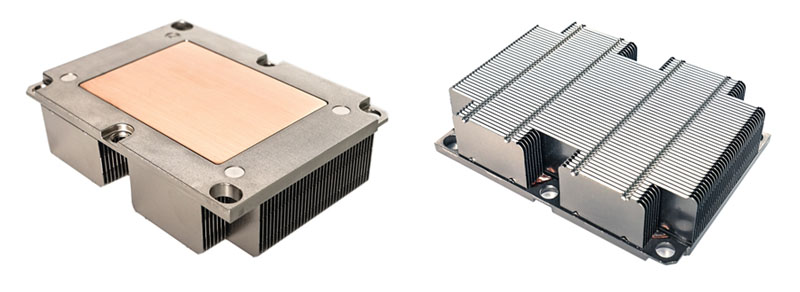

Stacked Fin Heat Sink Introduction:

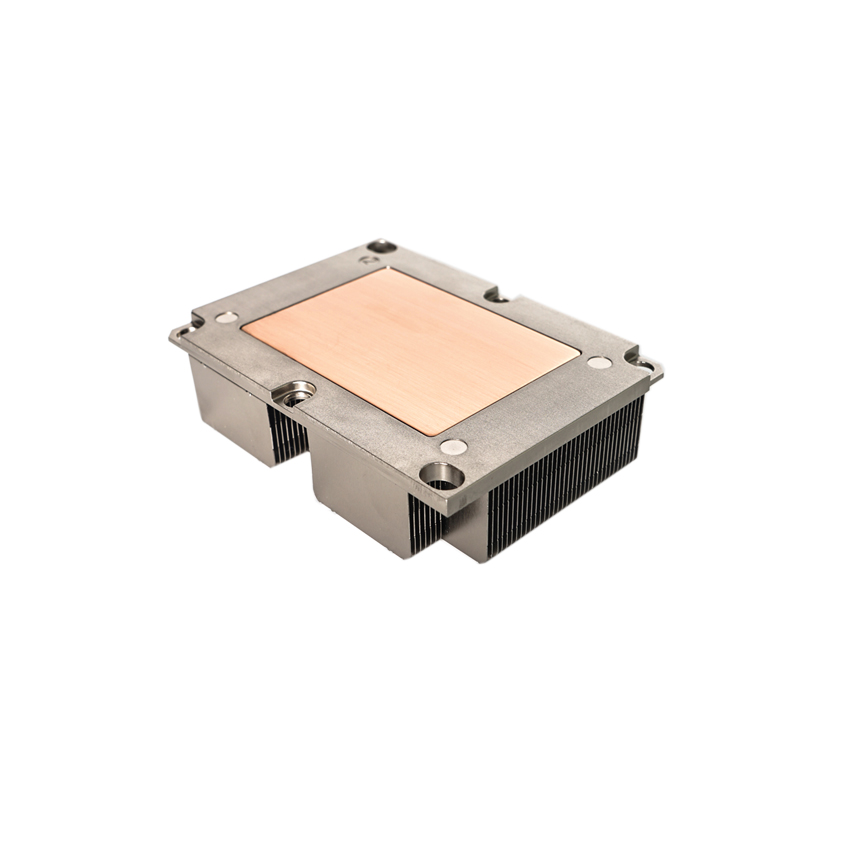

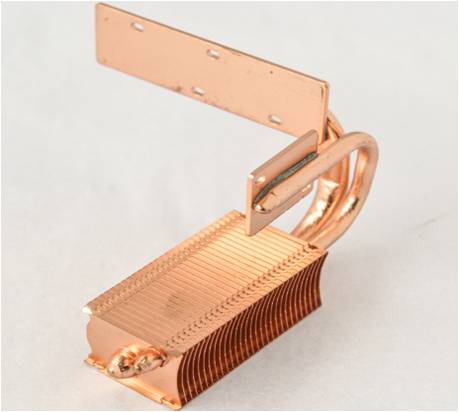

Stacked fin heat sink are formed by stamping allows for a cooling structure with both a top and bottom base plate for mounting power devices. When using this technology, no interface material is required for assembly, and it has the advantage of low development costs and a high degree of flexibility in forming heat sinks of different widths and structures, making it highly versatile. This technology has been widely used for cooling high-power devices such as power inverters and transformers, generators, etc.

The advantages of stacked heat sinks are the formation of a closed channel while increasing the cooling area, resulting in higher thermal performance, no limitation on volume, higher strength, lower manufacturing costs, easier installation and maintenance, longer service life, etc.

Stacked Fin Heat Sink process:

1. Stack fin made by stamping machine

2. CNC aluminum base and copper block

3. Stack fin and aluminum base nickel plated with 1.2um, thickness can be adjusted based on customer's requirement

4. Copper block anti-oxidation

5. Soldering stack fin, aluminum base and copper block by reflow oven

6. Degrease

7. Inspection, pack and ship

PT heat sink can customize stacked fin heat sink based on your thermal requirement and application. More important, we can design stacked fin heat sink and run simulation to find the best and cost reasonable solution for your application.

+86-18902844286

+86-18902844286

E-mail

E-mail