Advantages of Pioneer Thermal FSW Cold Plates

● High-quality welds with few defects (e.g., no porosity or cracks).

● Low distortion due to minimal heat input.

● Suitable for various metals (e.g., aluminum, magnesium, copper, titanium alloys).

● Environmentally friendly (no filler metals or shielding gases needed).

● Applications: Widely used in aerospace (aircraft structures), automotive (body parts), marine (hull structures), and electronics industries.

Applications of FSW Cold Plates in Electronics Cooling

● FSW-processed cold plates are used in various electronics cooling applications, including:

● High-Power Electronics: Cooling IGBTs, power MOSFETs, diodes, and other high heat-generating components.

● Electric Vehicles (EVs): Thermal management of battery packs, motor controllers, and onboard chargers.

● Data Centers: Cooling high-density computing equipment like servers, GPUs, and ASICs.

● Renewable Energy Systems: Cooling inverters for solar and wind power.

● Aerospace and Defense: Cooling embedded systems like radars, avionics, and power electronics.

● Medical Equipment: Thermal management in MRI machines, CT scanners, and laser systems.

● Industrial Automation: Cooling servo drives, motor controllers, and PLCs.

● Telecommunications: Cooling base stations, amplifiers, and routers.

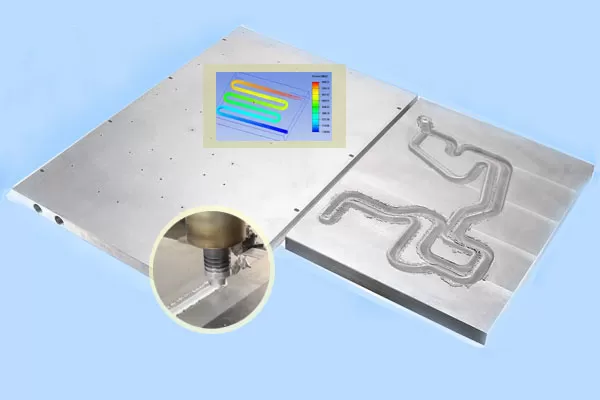

Pioneer Thermal FSW Cold Plate Services

How to choose a suitable FSW Cold Plates for your project depends on the chip's heating power, as well as the corresponding size, making process and material. These are all system level design solutions. Perhaps, we are the system level design supplier for the cooling field that you just need.

+86-18902844286

+86-18902844286

E-mail

E-mail