FAQs About Custom Heat Sinks

We typically need detailed specifications such as dimensions, mounting configurations, required cooling capacity (BTU or kW), flow rates, operating temperature and pressure, fluid type, and any special materials or coatings. If you have existing drawings, performance requirements, or technical standards, please share them as well.

Absolutely. We’ll start by reviewing your basic performance targets—such as heat dissipation, system pressure, flow rates, and space constraints—and then propose an optimal configuration.

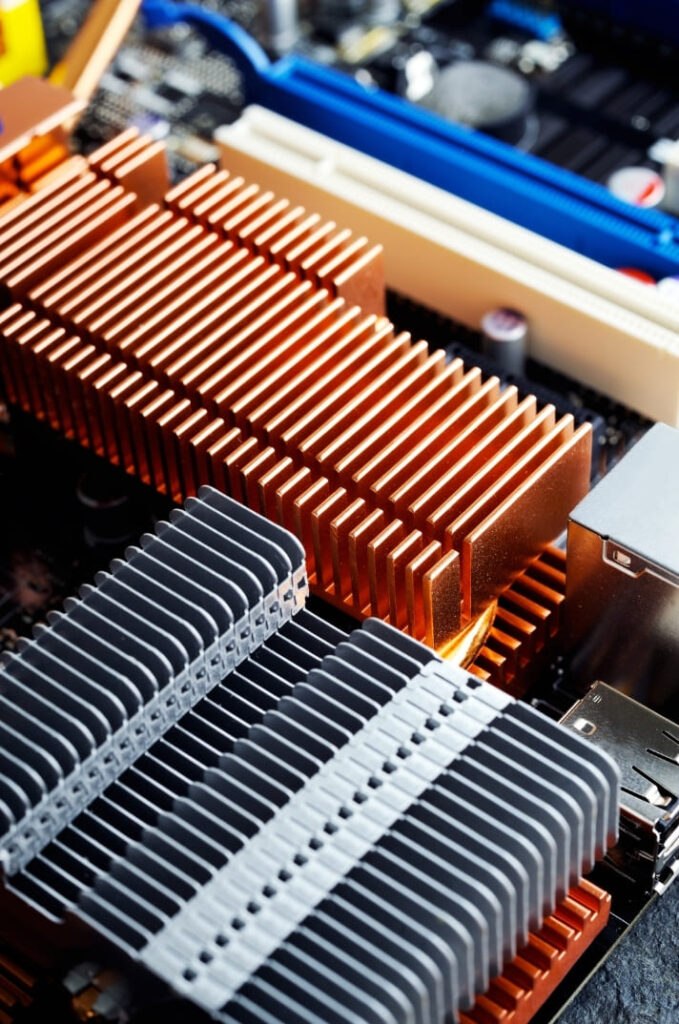

Our manufacturing methods include extrusion, CNC machining, skiving, and bonded fin construction.

Aluminum and copper are commonly used; aluminum is cost-effective and lightweight, while copper offers higher thermal conductivity for more demanding applications.

You’ll have a dedicated project manager who will provide regular updates, ensure timely responses to inquiries, and offer status reports at key milestones, from initial design approval through final delivery.

We can customize nearly every aspect, including fin configurations, tube types, core densities, mounting brackets, fittings, and inlet/outlet orientations. We also offer custom surface treatments, branding elements, integrated sensors, and advanced coating options.

Tags :

Nothing

+86-18902844286

+86-18902844286

E-mail

E-mail