Liquid cooling and thermosyphon systems are emerging as breakthrough solutions, offering 30–50% better thermal regulation while reducing energy consumption.

Liquid Cooling Plates: Precision Thermal Regulation

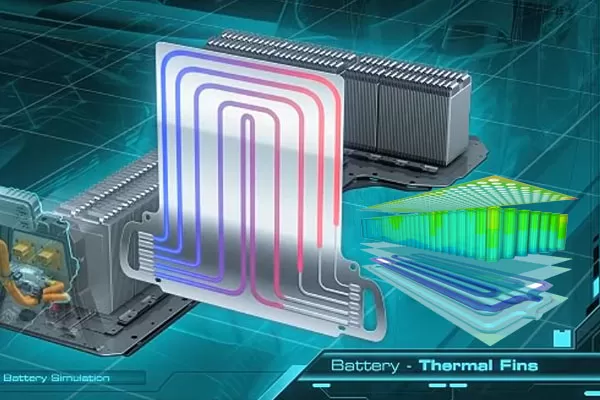

● Liquid cooling plates leverage the high thermal conductivity of coolants circulating through engineered microchannels, efficiently dissipating heat from battery cells. Available in stamped, extruded, or blow-molded designs, these lightweight aluminum alloy solutions offer exceptional thermal stability and adaptability across diverse battery configurations.

Direct Cooling (Thermosyphon) Plates: Next-Gen Efficiency

● Direct cooling systems utilize refrigerant phase-change technology, eliminating intermediate transfer steps to achieve 30% higher cooling efficiency. Mimicking air-conditioning evaporators, they provide rapid heat absorption during fast-charging cycles. Their compact design reduces energy consumption and space requirements, while non-conductive refrigerants enhance operational safety.

What Pioneer Thermal can offer:

Manufacturing Processes we have: Monolithic Blow-Molded, Brazed One-Piece, Modular Assembly etc.

For products we have:

1. Stamped & Brazed Plates: Lightweight, cost-effective for mass production.

2. Cold plate mainbody: Multi-channel parallel cooling for uniform heat dissipation.

3. Serpentine Tubes: Extended flow paths for linear temperature control.

4. Blow-Molded Cold Plates: Seamless channel-casing integration, superior leak resistance.

In the application of energy - power batteries, the innovation of thermosyphon technology is mainly reflected in the improvement of the working fluid and the optimization of the structure. The development of new high - performance working fluids with higher thermal conductivity and lower boiling point can improve the heat - transfer efficiency of the thermosyphon. At the same time, the use of fin - type heat exchangers and the optimization of the internal structure of the thermosyphon can increase the heat - transfer area and improve the heat - transfer effect.

If you need energy power batteries thermal management solutions, please contact Pioneer Thermal, we will design the project for you.

● Liquid cooling plates leverage the high thermal conductivity of coolants circulating through engineered microchannels, efficiently dissipating heat from battery cells. Available in stamped, extruded, or blow-molded designs, these lightweight aluminum alloy solutions offer exceptional thermal stability and adaptability across diverse battery configurations.

Direct Cooling (Thermosyphon) Plates: Next-Gen Efficiency

● Direct cooling systems utilize refrigerant phase-change technology, eliminating intermediate transfer steps to achieve 30% higher cooling efficiency. Mimicking air-conditioning evaporators, they provide rapid heat absorption during fast-charging cycles. Their compact design reduces energy consumption and space requirements, while non-conductive refrigerants enhance operational safety.

What Pioneer Thermal can offer:

Manufacturing Processes we have: Monolithic Blow-Molded, Brazed One-Piece, Modular Assembly etc.

For products we have:

1. Stamped & Brazed Plates: Lightweight, cost-effective for mass production.

2. Cold plate mainbody: Multi-channel parallel cooling for uniform heat dissipation.

3. Serpentine Tubes: Extended flow paths for linear temperature control.

4. Blow-Molded Cold Plates: Seamless channel-casing integration, superior leak resistance.

In the application of energy - power batteries, the innovation of thermosyphon technology is mainly reflected in the improvement of the working fluid and the optimization of the structure. The development of new high - performance working fluids with higher thermal conductivity and lower boiling point can improve the heat - transfer efficiency of the thermosyphon. At the same time, the use of fin - type heat exchangers and the optimization of the internal structure of the thermosyphon can increase the heat - transfer area and improve the heat - transfer effect.

If you need energy power batteries thermal management solutions, please contact Pioneer Thermal, we will design the project for you.

+86-18902844286

+86-18902844286

E-mail

E-mail